Hydraulic Iron Worker

Models List

-

KS55

-

KS75

-

KS110

-

KS140

-

KS200

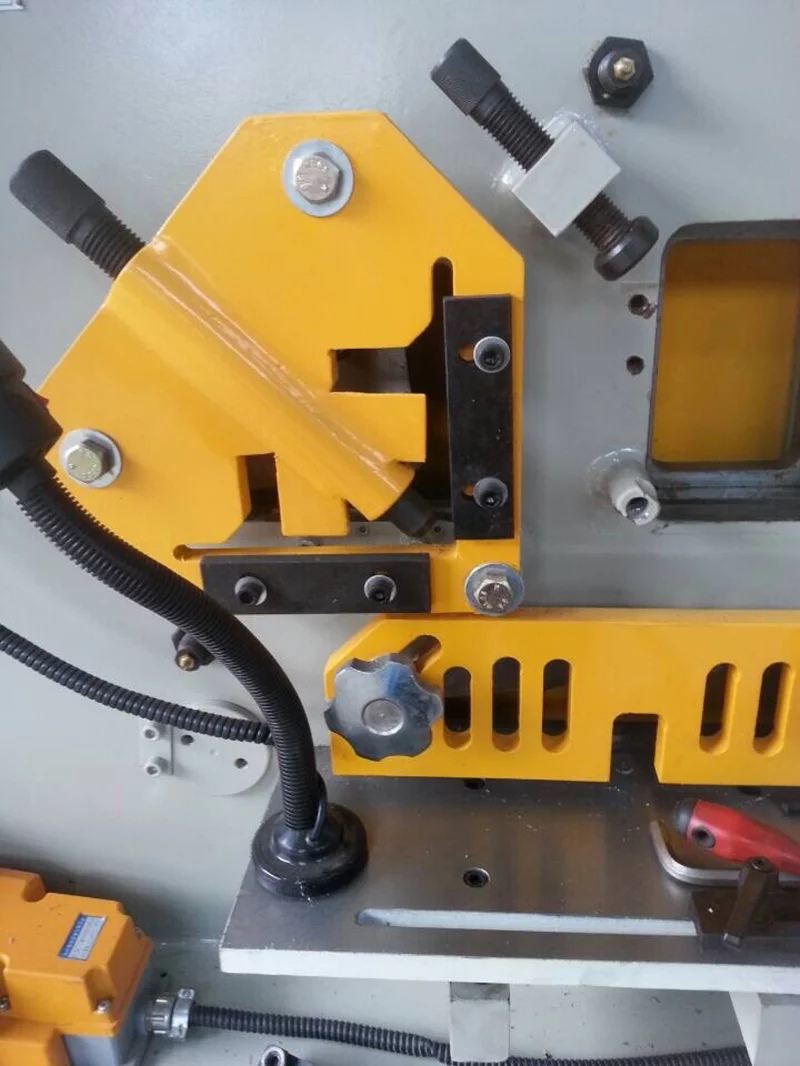

The KS Series multi-function Hydraulic Ironworker is the latest product in punching and shearing machines. It can cut, punch, notch, and bend various materials such as plate, flat bar, square bar, round bar, equal angle, channel, I-beam, and so on.

Product Overview

Lifeng Industrial hydraulic ironworkers are designed and built to the highest quality standards in the industry. This durable machine will serve any grueling fabrication shop for decades to come. The machine has received European Union CE certification and ISO quality system certification.

Product Application

The machine is widely used in industries such as steel, coal, high-speed railway, highway, automobile, shipbuilding, electric power, and others.

Main Features

- Punch hole

- Cut angle bar

- Cut round and square bar, channel bar, and I-beam

- Shearing plate

- Notching

Main Components

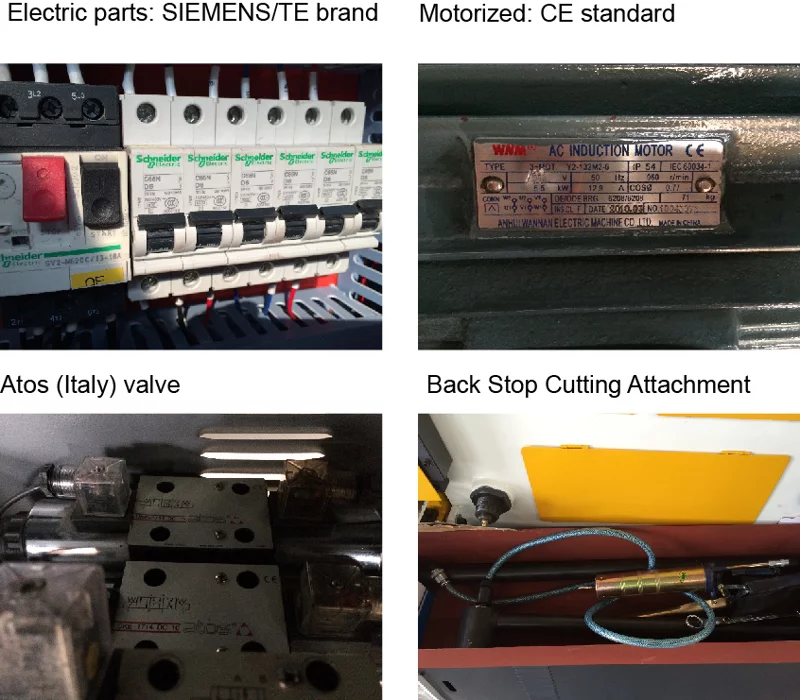

- Electric parts: SIEMENS/TE brand

- Motorized: CE standard

- Hydraulic system: ATOS (Italy)

- Valves: ATOS (Italy)

- Backstop cutting attachment: Automatically cuts when the sheet touches the stopper

Certifications

- ISO9001

- CE certificate

Workshop Photos

Optional Items

| Item | KS55 | KS75 | KS110 | KS140 |

|---|---|---|---|---|

| Punching Pressure Ton | 55 | 75 | 110 | 140 |

| Max Cutting Thickness mm | 16 | 20 | 25 | 30 |

| Plate Strength N/mm² | ≤450 | ≤450 | ≤450 | ≤450 |

| Angle Of Shear ° | 7 | 8 | 8 | 8 |

| Shearing Size Of One Stroke mm | 16x250 8x400 | 20x330 10x480 | 25x330 16x600 | 30x335 20x600 |

| RAM Stroke mm | 80 | 80 | 80 | 80 |

| Stroke Times S.P.M. | 12-28 | 18-30 | 9-18 | 8-16 |

| Throat Depth mm | 300 | 355 | 400 | 600 |

| Punch Depth mm | 16 | 20 | 25 | 28 |

| Max Punching Diameter mm | 25 | 30 | 35 | 38 |

| Main Power kW | 7.5 | 7.5 | 7.5 | 11 |

| LxWxH mm | 1700x750x1800 | 1950x900x1950 | 2355x960x2090 | 2800x1100x2500 |

| Weight Kg | 1800 | 2200 | 4800 | 6200 |

| Round Bar | 45 | 50 | 60 | 65 |

| Square Bar mm | 40x40 | 40x40 | 40x40 | 40x40 |

| Equal Angle 90°Shearing mm | 125x125x12 | 140x140x12 | 160x160x14 | 180x180x16 |

| Equal Angle 45°Shearing mm | 70x70x8 | 70x70x10 | 80x80x7 | 80x80x10 |

| T-Bar 90°Shearing | 120x120x12 | 140x70x12 | 160x160x14 | 180x180x16 |

| T-Bar 45°Shearing | 60x60x8 | 70x70x10 | 80x80x10 | 80x80x10 |

| I-Bar | 126x74x5 | 200x102x9 | 200x102x9 | 280x124x10.5 |

| Channel | 126x53x5.5 | 160x60x6.5 | 200x75x9 | 280x86x11.5 |

| Item | KS200 |

|---|---|

| Punching Pressure Ton | 200 |

| Max Cutting Thickness mm | 40 |

| Plate Strength N/mm² | ≤450 |

| Angle Of Shear ° | 8 |

| Shearing Size Of One Stroke mm | 40x335 30x600 |

| RAM Stroke mm | 100 |

| Stroke Times S.P.M. | 8-16 |

| Throat Depth mm | 600 |

| Punch Depth mm | 30 |

| Max Punching Diameter mm | 40 |

| Main Power kW | 18.5 |

| LxWxH mm | 2800x1100x2500 |

| Weight Kg | 9200 |

| Round Bar | 70 |

| Square Bar mm | 40x40 |

| Equal Angle 90°Shearing mm | 200x200x18 |

| Equal Angle 45°Shearing mm | 80x80x10 |

| T-Bar 90°Shearing | 200x200x18 |

| T-Bar 45°Shearing | 80x80x10 |

| I-Bar | 280x124x10.5 |

| Channel | 300x89x11.5 |