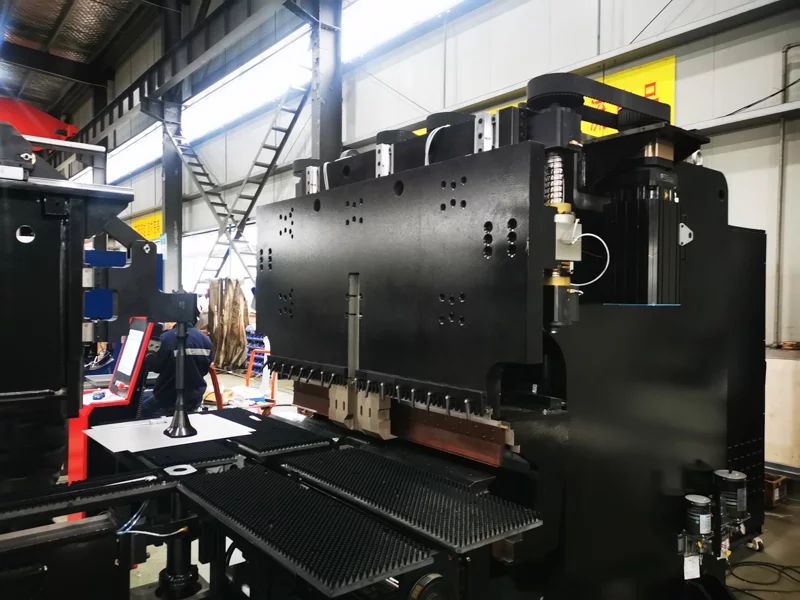

CNC Panel Bending Center

1 Overview of KISTON Panel Bender

According to the design concepts of savanini and prima power, the structural design of the core components of the machine tool is original, so as to avoid the impact of structural defects on the bending accuracy and plate thickness, such as integral body, direct drive plate rotation, bending driving mode, etc. various accessories are selected according to high standards and strict requirements, and through rigorous structural design and theoretical calculation, Ensure the service life and stability of the equipment, and the brand, model and specification of main accessories far exceed that of domestic equipment.

In addition to the above main advantages, our equipment is strictly implemented in accordance with foreign technical indicators in terms of processing technology, assembly technology and quality requirements. The control system, transmission parts and processing parts are configured in high standards to ensure the processing efficiency, processing accuracy and stability of the equipment.

2 Main Advantages of Wisdom Panel Bender

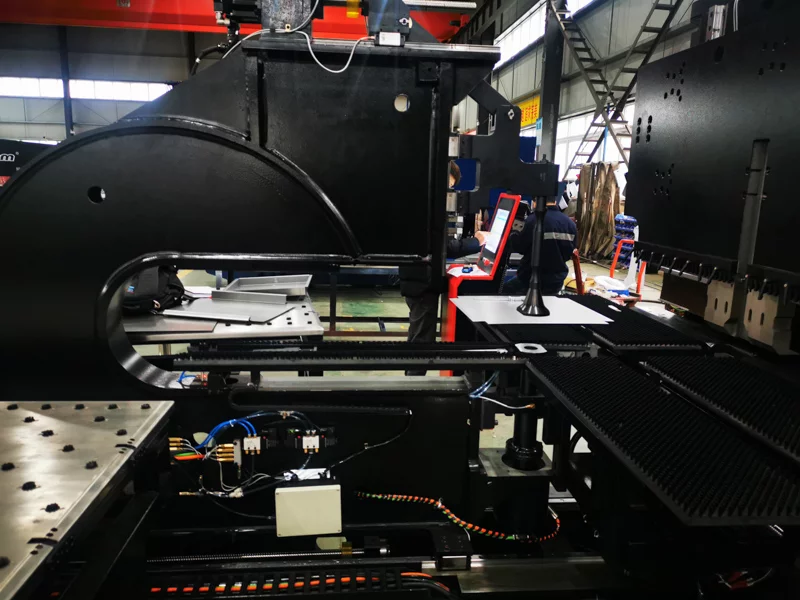

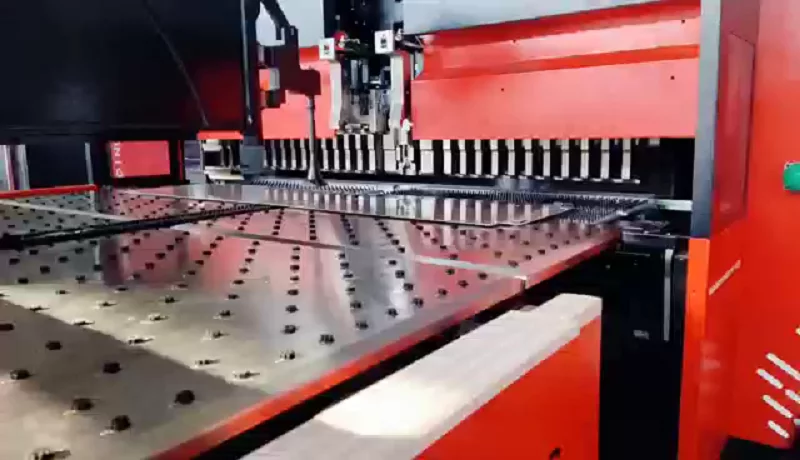

All axes of the full electric servo multilateral bending center are controlled by servo motor. The plate is automatically positioned and rotated to realize one-time positioning and automatically complete the multilateral positive and negative bending without manual feeding and turnover, which saves labor and processing time, realizes intelligent processing, and has good consistency of parts and components.

1. The design of frame and C-shaped bending unit is designed in cooperation with a university, all of which adopt finite element analysis, and the material is Q345 steel; Carbon dioxide shielded welding; Conduct tempering treatment to eliminate the stress caused by welding; So as to improve the rigidity, enhance the anti-deformation ability and ensure the accuracy of parts.

2. Servo motor control is adopted, with lower energy consumption compared with traditional hydraulic control.

3. Servo motor control is adopted, with automatic lubrication as the key point and lower maintenance cost

4. Servo motor control is adopted, with higher control accuracy and consistency.

5. Servo motor control is adopted, with low equipment operation noise

6. Realize the automatic positioning and rotation of plates without the participation of personnel, eliminate the occurrence of industrial accidents, improve the consistency and efficiency of products

7. The upper and lower platen pressing method is adopted to ensure the feeding accuracy of plates

8. DD motor is adopted to ensure the rotation accuracy of plate. C-type bending unit is adopted to realize positive and negative bending and improve production efficiency

9. C-type bending unit and special bending track are adopted to make the surface scratch of bending parts smaller

10. The universal upper pressing unit can automatically adjust the die length according to the plate length without manual die change, making the bending more flexible and efficient

11. Special box avoidance design makes bending more flexible.

12. Movable bending unit design meets more complex requirements of customers and improves production efficiency

13. The professional design team can design and develop customized equipment.

14. according to the requirements of customers' parts, so as to provide more powerful equipment guarantee for factory automation in the future.

15. It adopts Ether CAT bus control mode with strong anti-interference ability.

16. It supports two-dimensional programming function and imports two-dimensional DXF drawing data

17. It can realize positive and negative bending, arc bending, flattening bending, special bending and other bending processes

3 Specification

| Model | EMBC-2502 |

| parameters | |

| Max. sheet length (mm) | 2500 |

| Max. sheet width (mm) | 1500 |

| Ether CAT diagonal(mm) | 2800 |

| Min. bending length(mm) | 250 |

| Min. bending width(mm) | 125 |

| Mi. Bending thickness(mm) | 0.5 |

| Upper press device length adjustment model | Automatic |

| Mex. bending height(mm) | 200 |

| Average energy consumption(KW) | 7 |

| Weight(T) | 18 |

| Size(L*W*H)(mm) | 5200*3200*2800 |

| Max. thickness and bending angle MS, UTS410N/mm²(mm) | 2.0 (± 90°) |

| Matchiness and bending angle SS,UTS600N/mm²(mm) | 1.2(± 90°) |

| Matchiness and bending angle Aluminum,UTS265N/mm²(mm) | 3.0 (± 90°) |

4 Configuration

| No. | Name | Brand |

| 1 | Body | EMBC-2502 |

| 2 | CNC System | Wisdom |

| 3 | Servo system | Xuanwu |

| 4 | Servo driver | by storm |

| 5 | Reducer | STY Gear |

| 6 | Tool | Wisdom |

| 7 | Breaker | Schneider |

| 8 | Relay | Schneider |

| 9 | Ball screw | Nanjing Technical |

| 10 | Rail | Rexroth |

| 11 | Pneumatic parts | SMC |

| 12 | Bearing | FAG |

| 13 | Bearing | NACIH |