Tube Bending Machine

Models List

-

A15CNC

-

A25CNC

-

A38CNC

-

A50CNC

-

A63CNC

-

A75CNC

-

A89CNC

CNC Pipe Bender is the advanced Pipe Bender with multi-axis servo motor controlling and multi-layer mould function. Desighed by GBEMA, a historical Italia Pipe Bender company, this machine applys professional skills of industrial computer and CNC Pipe Bender into multi-axis servo motor and hydraulic servo driving. It can work automaically like feeding,rotating,changing moulds, reading drawings, editing andrevising technical documents and correcting datas.What’s more, working with robots, it also can loading and unloading automaitcally, testing pipes and revise technical datas and production procedures according to the test result.It can diagnose fault automaically, 3D pipe display and simulation,3D interference detection,etc.It is the first choice for the field of aerospace,nuclear power, automobile, motorcycle, shipbuilding, petrochemical,electricity, gas, boilers, fitness and sports equipment to bending pipes. 1-9stack tooling is optional.

| Item | A15CNC | A25CNC | A38CNC | A50CNC |

|---|---|---|---|---|

| Max. OD× WT mm | 19.05×1.5 | 25.4×1.5 | 38.1×2 | 50.8×2.5 |

| Max. OD× WT mm | 15.88×1.5 | 19.05×1.5 | 31.75×1.5 | 44.45×2 |

| Max. Square Tube × WT mm | 15×1.5 | 20×1.5 | 30×1.5 | 40×2 |

| Max. Round Bar mm | 12 | 18 | 25 | 32 |

| Max. Bending Radius mm | 100 | 100 | 160 | 200 |

| Mandrel Working Distance mm | 1200 | 1500 | 1900 | 2300 |

| Max. Bending Angle deg | 0-190 | 0-190 | 0-190 | 0-190 |

| Tube Bending Speed deg | 200 | 180 | 180 | 110 |

| Feeding Speed | 1300 | 1300 | 1200 | 1200 |

| Rotating Speed | 360 | 360 | 360 | 270 |

| Feeding/Rotating/Bending Precision mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 |

| Max. Working Pressure MPa | 14 | 14 | 17.5 | 17.5 |

| Pump Motor kW | 2.2 | 4 | 5.5 | 7.5 |

| Oil Tank Capacity L | 160 | 210 | 250 | 300 |

| Overall Weight Kg | 850 | 1000 | 1500 | 200 |

| Operating Height mm | 900 | 1015 | 1015 | 1100 |

| LxWxH mm | 2400x700x1300 | 3500x800x1350 | 4000x850x1400 | 4900x1050x1400 |

| Item | A63CNC | A75CNC | A89CNC |

|---|---|---|---|

| Max. OD× WT mm | 63.5X3 | 76.2×3 | 88.9×4 |

| Max. OD× WT mm | 63.5X1.5 | 76.2×1.5 | 88.9×2 |

| Max. Square Tube × WT mm | 50X2.5 | 60×3 | 70×3.5 |

| Max. Round Bar mm | 38 | 45 | 55 |

| Max. Bending Radius mm | 270 | 280 | 350 |

| Mandrel Working Distance mm | 2800 | 3000 | 3300 |

| Max. Bending Angle deg | 0-190 | 0-190 | 0-190 |

| Tube Bending Speed deg | 100 | 90 | 80 |

| Feeding Speed | 900 | 800 | 800 |

| Rotating Speed | 250 | 250 | 240 |

| Feeding/Rotating/Bending Precision mm | ±0.1 | ±0.1 | ±0.1 |

| Max. Working Pressure MPa | 17.5 | 17.5 | 17.5 |

| Pump Motor kW | 7.5 | 11 | 15 |

| Oil Tank Capacity L | 300 | 380 | 500 |

| Overall Weight Kg | 2900 | 3500 | 4500 |

| Operating Height mm | 1100 | 1150 | 1200 |

| LxWxH mm | 4900x1050x1500 | 5300x1300x1550 | 6000x1600x1550 |

The frame is assembled in monoblock after welding

The frame is assembled in monoblock after welding, it is processed by heating treatment, machining by CNC Floor Boring and Milling center, ensuring the rigidity and processing accuracy of the frame.

YUKEN hydraulic system and pump

YUKEN hydraulic system and pump , making sure the machine working stabilization

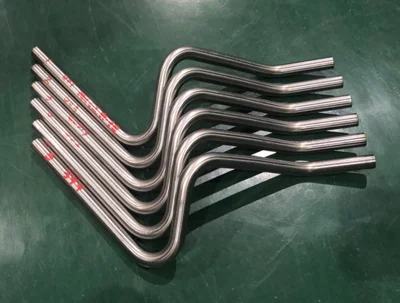

all tool set die adopt slow speed wire cut and CNC machine making

Bending die , clamping die , pressure die , mandrel and wiper die (optional ) , all adopt slow speed wire cut and CNC machine making , the material all adopt 42CrMo , making sure the use life

Mitsubishi PLC control

CE standard electrical parts, Mitsubishi PLC control, Schneider electrical parts

Touch screen setting all parameters

(bending degree , feeding length , rotating degree) ,Manual /semi auto /fully auto working model, Chinese /English language

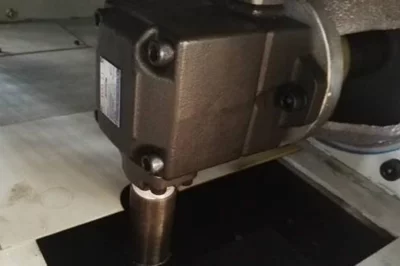

Servo motor bending

This is optional , usually , only use hydraulic cylinder driven the bending , if you looking high speed with high precision , we suggest the servo motor ( Mitsubishi servo motor )