CNC Laser Cutting Machine

1 Main Advantages

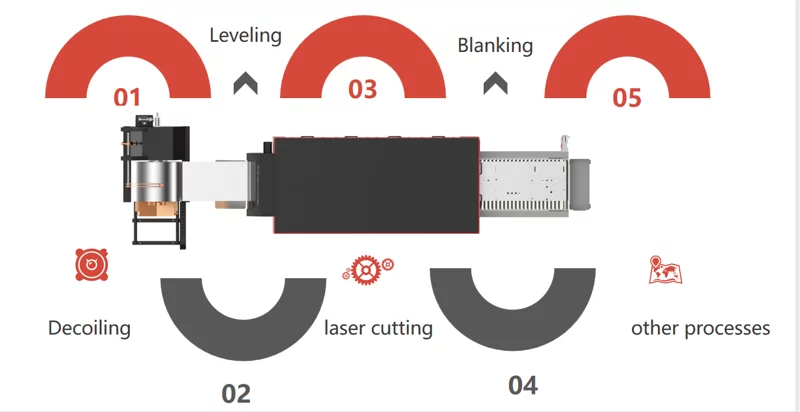

2 Process Flow

- Uncoiling the coil,the coil is brought by crane and put on the feeding cart.The cart moves the coil and uses its hydraulic cylinder to lift coil at the right height where the feeding platform of cart equals to uncoiler’s core axes, then the axes moves into the inner hole of the coil,the raw-material uploading is finished. Once accepted the coil, the uncoiling spindle expands and shrinks by rotating the oil cylinder, in order to firmly stuck the coil hole and decoiling by tension.

- Through the precision leveling machine, when the sheet material enters the feeding roller of the leveling machine, the sheet material enters the leveling roller system, and the sheet material repeatedly yields after the extrusion of the upper and lower leveling roller, so as to achieve accurate leveling.

- Through the linear guide rail and transmission platform to transport the plate, the plate is transmitted while laser cutting. At the same time, laser marking and labeling can also be carried out.

- The robot's gripper is mainly composed of vacuum sucker and electromagnet, and each gripper is controlled uniformly.The the arm’s cylinder drives the vacuum sucker to push out, and separates the leftover materials and finished products, and places them in the designated area. The gap of vacuum suckers and electromagnets can be adjusted through numerical control system, to meet the shape and size requirements of different products. Note:Functions of marking and automatic stacking are optional.

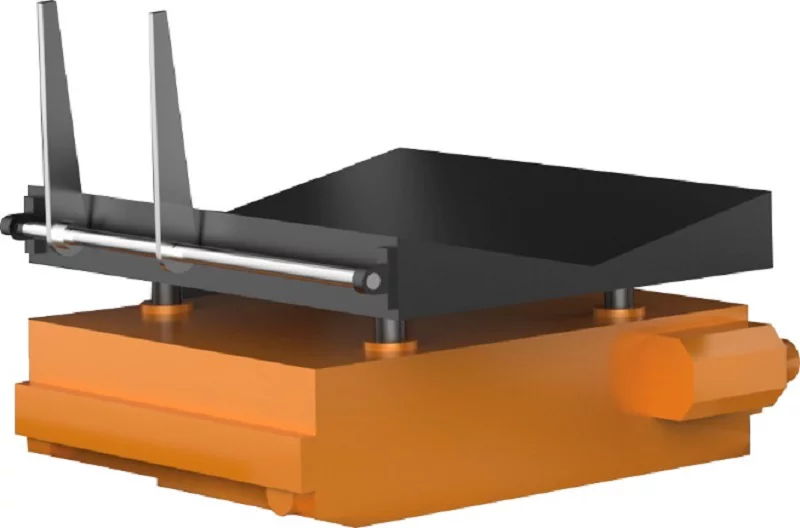

3 Feeding Lifting System

The feeding trolley is located on the outer end face of the mandrel of the uncoiler, and the hydraulic cylinder lifts the steel coil. When working, hang the coil plate on the tray at the top of the oil cylinder, and the hydraulic cylinder lifts the coil plate to the center of the uncoiler mandrel. After the feeding is in place, the uncoiler will make the arc plate expand and shrink through the oil cylinder for the uncoiler to tighten. then, the trolley descends, and the trolley returns to the next loading position.

4 Uncoiler System

| 1 | Bearing wieight | ≤10t |

| 2 | Width of coil | ≤1300 mm |

| 3 | Outer diameter of coil | 1000~2000mm |

| 4 | Expansion range | Φ480~520mm |

| 5 | Wedge slider | 45# Steel Quenching and Tempering HB225~255 |

| 6 | strip hold down roll | Polyurethane coated |

| 7 | Drum surface | Hard chromium plating |

| 8 | Braking / tensioning | Pneumatic disc brake |

| 9 | Expanding oil cylinder | Engineering cylinder |

| 10 | Pressure and pilot driver | Hydraulic motor |

| 11 | Pressure and pilot cylinder | Engineering cylinder |

| 12 | Auxiliary support cylinder | Engineering cylinder |

| 13 | technology of main parts | Integral aging treatment of frame steel plate welding |

| 14 | lubrication | Manual fixed-point lubrication |

5 Introduction System

It is used for threading the material coil, connecting and guiding the plate head, and making the plate head enter the pinch roll smoothly through the straight head

It is composed of frame, guide tongue table, straight head, etc.

The frame is welded by steel plate and shape steel

The hinge-point swing of the guide shovel head(hardened) is lifted and lowered by the oil cylinder, the expansion plate is driven and expanded by the oil cylinder, and the guide plate head is connected for transition

| 1 | Material and heat treatment of main parts | Welding and annealing treatment of frame steel plate |

| 2 | Support plate, guide plate | 45# steel, Quenched and tempered, surface chrome plated |

| 3 | Shovel head cylinder | Engineering cylinder |

| 4 | Straight head cylinder | Engineering cylinder |

| 5 | Telescopic cylinderv | Engineering cylinder |

| 6 | lubrication | Manual dry oil lubrication gun |

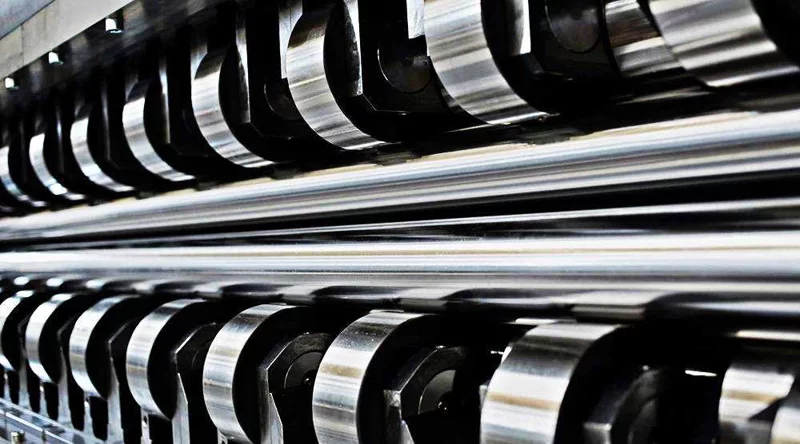

6 Leveling System

Support-roll-construction,digital displayed leveling process. When changing the material thickness, it can reach the specified position quickly and simply. With the functions of motor adjustment, intelligent shutdown, forward and reverse one-button conversion, it makes the equipment more efficient and stable operation more convenient.

6-fold 24 rollers leveling equipment, mainly used in stainless steel, Bimetallic Sheet, Galvanized Sheet, Nonferrous Metal Sheet, And aluminum ,which can keep the surface smooth and avoid surface indentation

7 Leveling System-Power Part

The machine is designed with two-stage power drive. The power of the main motor is transmitted to the power distribution box with gear structure through the reducer. Each leveling work roll has driving force input. The power mechanism, composed of motor, reducer, coupling, power distribution box, universal transmission shaft, drives the upper and lower rows of work rolls from end of rolls at the same time. The main force is from high-power DC motor, which is responsible for providing power to the leveling unit, at the same time, the DC motor starts at low speed, with high torque and fast response speed when making and breaking frequently. Equipped with high-end digital DC controller, the production line has high production efficiency and good length fixing accuracy.

8 Leveling System- Rollers

The roller end bearing adopts precision needle roller bearing to connect the roller shaft seat, and the running resistance is small. The upper and lower working rollers and the upper and lower cross beams are provided with middle rollers and support rollers which feature Finish grinding after quenching, and slightly lower hardness compare with work rolls. Most of the bending force generated by the work roll is borne by the middle roll and support roll. The middle roller can also isolate the mark brought by the feedback of the backup idler to the work roller on the plate surface, so as to ensure that the surface is not damaged after passing through the leveler. Multiple groups of support rolls work together with middle roll and work roll to greatly improve the stiffness and strength of work rolls. The height and direction of the idler base are adjusted with wedges, which can not only reduce the deformation of the work rolls, but also easier to adjust. The support roll and the roll shaft base are connected by bearings.

9 Laser Cutting System

The machine adopts professional machine bed structure, aging annealing treatment, high precision rack and rail drive mechanism, plus Yaskawa servo motor, so that all the moving parts run fast and stable. The moving part of the bed is equipped with automatic lubrication system, and the German technical numerical control system makes the cutting of the equipment stable, fast with high precision. 6000W laser tool can cut aluminum plate, carbon steel, stainless steel galvanized plate and so on.

| 1 | Cutting working table size | 1300mm*3000mm |

| 2 | Unloading working table size | 1300mm*3000mm |

| 3 | X-aixs stroke | 1300mm |

| 4 | Y-aixs stroke | 3000mm |

| 5 | Z-aixs stroke | 150mm |

| 6 | Positioning accurancy | ±0.5mm |

| 7 | Repeat positioning accurancy | ±0.3mm |

| 8 | Max cutting speed | 40m/min |

| 9 | Max feeding speed | 16m/min |

| 10 | Platform load-bearing | 1 ton |

10 Laser cutting system -configuration

| Item | Brand | Origin | Unit |

| CNC control System | Beckoff | Germany | 1 |

| Nesting software | cncKad | Israel | 1 |

| Servo Motor | Yaskawa | Japan | whole sets |

| Linear Guide rail | HIWIN | Taiwan | whole sets |

| Gear rack pinion | YYC | Taiwan | whole sets |

| Machine servo drivers | Yaskawa | Japan | whole sets |

| Pneumatic Components | SMC | Japan | whole sets |

| Laser source | MAX 6000W | China | 1 set |

| Laser head | Precitech Procutter2.0 | Germany | 1 set |

| Chiller | Tongfei | China | 1 set |

| Air condition | Tongfei | China | 1 set |

| Low voltage electrical components | Schneider | France | whole sets |

| Feeding platform | Yaskawa | Japan | whole sets |

| Unloading platform | Yaskawa | Japan | whole sets |

Machine Bese of CNC Laser Cutting Machine

The machine base adopts a superposed-welded one-piece machine body, which is treated to eliminate internal stress after annealing. After rough machining, vibration aging is performed before finishing, which greatly improves the rigidity and stability of the machine bed and ensures the cutting accuracy.

Laser source Max 6000W

The highest market share in market proves its superior and stable performance. Cost-effective High electro-optical conversion efficiency Output fiber length can be customized QBH/QD connector Maintenance-free operation Wide modulation frequency range Small size, easy to install

Precitech Lightcutter

The cutting head LightCutter Zoom 2.0 provides a maximum and flexible performance in a minimum of space. It generates the perfect beam for all materials in all thicknesses for laser powers up to 6 kW and is therefore the ultimate all-rounder for your flatbed system

6 axis robot arm for unloading

TYPE: ESTUN ER220-2650 Wingspan:2650mm Repeat positioning accurancy: ±0.02mm Max load eight:220kg Axis:6 axis We need to know your more clearly parameters

Gantry system for unloading-Plan A

We need to know your more clearly parameters

laser marking system

Power 20/30/50w Self-adjusting speed and output power Industrial exterior design; Marking area: 100*100-300*300mm Max making speed:8000mm/s. Languages: Chinese, English, French, German, Spanish, Russian

UPS

The industrial-grade UPS series is specially designed for relatively special operating environments such as power plants, petrochemicals, metallurgical industries or other conventional equipment power supply systems. It adopts the input and output double isolation design to effectively enhance the UPS's ability to withstand voltage and load shocks; the use of advanced The advanced DSP digital control technology makes the whole machine have high reliability and fast transient response; the whole machine adopts a modular design, and the maintenance is very simple.