H Type Single Point Press Machine

Models List

-

APF-110

-

APF-160

-

APF-200

-

APF-260

-

APF-300

-

APF-400

-

APF-500

-

APF-600

| Item | Brief Description |

| Machine Body | Steel plate welded structure, through vibration aging treatment, the overall heat ageing annealing treatment. (Double aging treatment) |

| Bolster | Made from Casting HT200,through annealing treatment |

| Crank | Made from Forging, through flaw detection ,surface quenching, nitriding processing |

| Fly Wheel | Casting HT200,Through Annealing Treatment |

| Worm | Zinc-based alloys |

| Worm Gear | Made from 45# steel |

| Connecting Rod | Made from Ductile iron, cast iron, and throughnormalizing treatment |

| Ball Head and Screw | Made From 45# steel, surface by Nitriding treatment |

| Balance Cylinder | Cylinder Body Inside Through Honing Processing |

| Machine body | Steel metal machine body, iron cast working table |

| Gears | Forging die gear grinding with Germany N1LES grinding machine; |

| Inverter | TECO ( Taiwan ) |

| Motor ` | TECO ( Taiwan ) |

| Double-solenoid valve | TACO ( JAPAN ) |

| CLUTCH | OMPI ( Italy ) |

| Over-load protector | KINGAIR ( Taiwan ) |

| Bearing | NSK ( Japan ) |

| Oil seals | NOK ( Japan ) |

| Contactor and other parts | Schneider |

| Air adapter | 3A ( Korea) |

| Nuts/screw and fastener | MaoYi ( Taiwan) |

Detail Parts Production Process:

Forging Crank:

- Complete one-piece forging, not welding type.

- Crank Grinding:

- The crank first goes to the lathe machine, then to the grinding machine. One crank takes 7 hours in the grinding process.

Machine Frame:

- First, a plasma cutting machine is used to cut the steel plate. Before welding the frame, we use a beveling machine to bevel the steel. The frame is then fully welded, making the body stronger. This is followed by shot blasting and painting.

Advanced Equipment for Machine Body Process:

- CNC Floor-Type Boring Machine:

- Ensures high precision.

- High Precision Gear:

- Keeps the machine running with low noise. Made by Germany NILE Grinder.

- Ram Assembly:

- Every ram is stamped with a code to ensure assembly quality.

- Electrical Parts:

- All parts adhere to CE standards. Main parts are from Schneider.

Customer References:

Customer Reference in the UK:

- Nico Manufacturing Ltd

- 109 Oxford Road,

- Clacton-On-Sea, Essex. CO15 3TJ

Customer Reference in CA:

- Future Steel Buildings Intl. Corp.

- 220 Chrysler Drive,

- Brampton, Ontario,

- Canada, L6S 6B6

| Item | APF-110 | APF-160 | APF-200 | APF-260 |

|---|---|---|---|---|

| Capacity ton | 600 | 500 | 400 | 300 |

| Rated Tonnage Point mm | 3.5 | 7 | 3.5 | 7 |

| Stroke mm | 150 | 250 | 100 | 200 |

| Speed Changing s.p.m | 40-50 | 20-40 | 50-70 | 20-50 |

| Stable Speed s.p.m | 20 | 20 | 20 | 30 |

| Die Height mm | 550 | 500 | 510 | 460 |

| Slide Adjustment mm | 120 | 120 | 150 | 120 |

| Slide Area mm | 1400x1200 | 1400x800 | 1500x850x110 | 1400x800x110 |

| Bolster Area mm | 1700x1300 | 1500x1000 | 1600x1000x200 | 1500x950x200 |

| Side Opening mm | 1000x900 | 900x800 | 1000x750 | 1000x750 |

| Main Motor kW x p | 75x4 | 55x4 | 40x4 | 30x4 |

| Slide Adjusting Motor kW x p | 3x4 | 3x4 | 2.2x4 | 1.5x4 |

| Air Pressure kg/cm² | 6 | 6 | 6 | 6 |

| Item | APF-300 | APF-400 | APF-500 | APF-600 |

|---|---|---|---|---|

| Capacity ton | 260 | 200 | 160 | 110 |

| Rated Tonnage Point mm | 3 | 6 | 3 | 6 |

| Stroke mm | 90 | 200 | 80 | 180 |

| Speed Changing s.p.m | 40-70 | 20-50 | 60-90 | 30-60 |

| Stable Speed s.p.m | 30 | 35 | 35 | 50 |

| Die Height mm | 510 | 460 | 410 | 360 |

| Slide Adjustment mm | 120 | 110 | 100 | 80 |

| Slide Area mm | 1300x700x100 | 1200x650x90 | 1100x600x90 | 1000x550x70 |

| Bolster Area mm | 1400x840x180 | 1300x820x160 | 1200x800x140 | 1100x600x110 |

| Side Opening mm | 900x700 | 880x650 | 850x600 | 700x500 |

| Main Motor kW x p | 22x4 | 18x4 | 15x4 | 11x4 |

| Slide Adjusting Motor kW x p | 1.5x4 | 0.75x4 | 0.75x4 | 0.4x4 |

| Air Pressure kg/cm² | 6 | 6 | 6 | 6 |

Inverter

It works mainly for speed regulation, convenient for mold installation and trial by operators as well as machine maintenance.

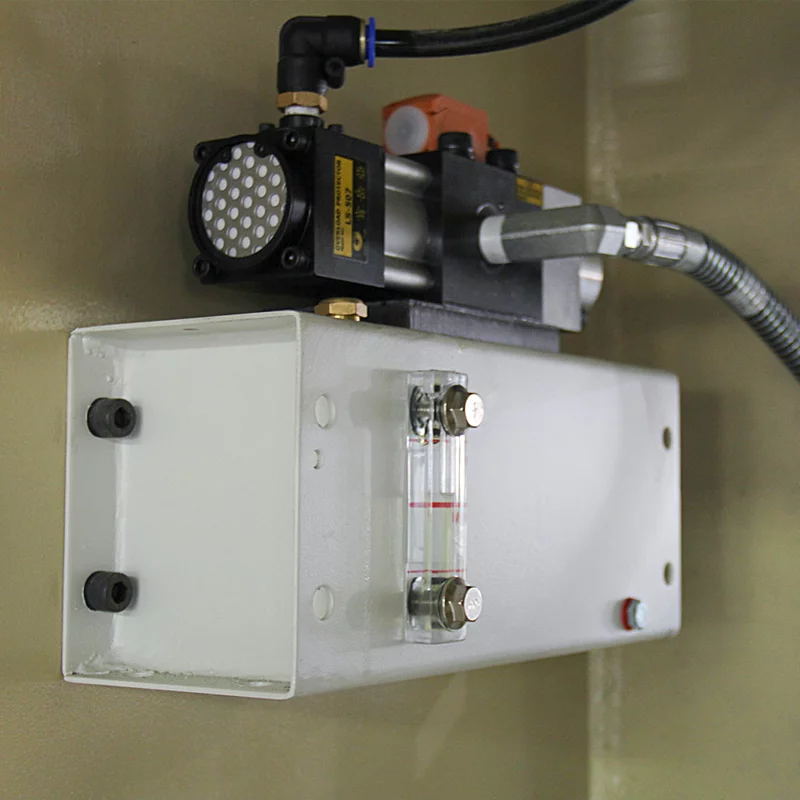

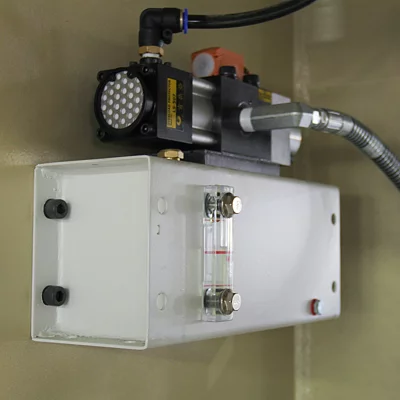

Hydraulic overload protection pump

When the pressure of slider exceeds its specified pressure, the overload pump will relieve the pressure to protect the stressed part of press machine from damage.

Auto grease lubrication device

It works under PLC control, providing lubrication for guide rails, crankshaft bearing bush, etc. without manual interference, realizing automatic lubrication

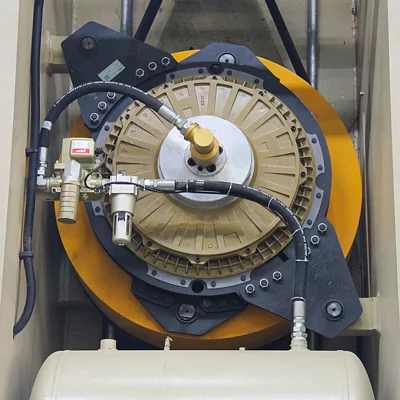

Clutch and brake integrated

The function of clutch and brake is to control the movement and stop of slider, its sensitivity directly relates to safety issues, it works on the purpose of protecting the operators and press machine.

Digital die height indicator

Balancer and clutch pressure meter

The pressure of overload protection pump is generally adjusted at 0.4MPa, clutch and brake pressure at 0.6MPa, balancer pressure at 0.4MPa.

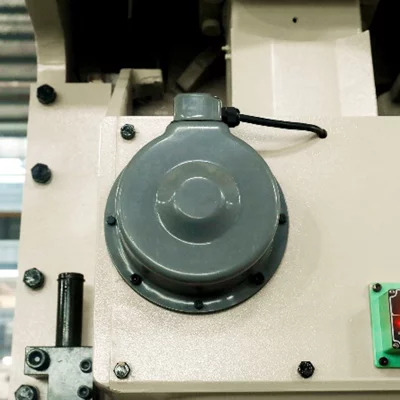

Slide adjustment motor

The motor drives the slider, which moves up and down to adjust the distance between slider and working table. When the distance is adjusted well, motor stops working.

Touch screen ( APA 110 electric box with machine body together )

Multi language touch screen control system. It displays a series of press parameter, such as SPM (strokes per minute), electronic cam angle etc. You may set other corresponding data through this touch screen.

Hands operation panel ( Optional ) extra USD 500/set

When operators start the machine, they need to press the left and right buttons at the same time, which is to avoid potential safety risks when operators start the button while operating the machine.